42 time temperature transformation diagram

Why TTT diagram is c shaped? We have mentioned before, TTT diagram is time and temperature transformation diagram.Pearlitic transformation is a diffusion-based transformation which involves solid-state conversion into alpha iron and iron carbide colonies. Without the required temperature and time, diffusion is not possible, and structure will, then, have martensite or bainite transformations. Time-Temperature-Transformation (TTT) Diagrams 1. Classification of Phase Transformations and Plasticity Civilian transformation Military transformation 2. Table 3.5 Classification of Nucleation and Growth Transformations ... It takes time for atoms to attach to ...

Generalized isothermal time-temperature-transformation (TTT) cure diagram for a thermosetting system, showing three critical temperatures (T g0 , gel T g , and T g∞ ), various stages of the ...

Time temperature transformation diagram

Creation of time-temperature-transformation diagrams and what information we can extract from themLearning goals:- You describe the formation and occurrence ... Isothermal transformation diagrams (also known as time-temperature-transformation (TTT) diagrams) are plots of temperature versus time (usually on a logarithmic scale).They are generated from percentage transformation-vs time measurements, and are useful for understanding the transformations of an alloy steel at elevated temperatures.. An isothermal transformation diagram is only valid for one ... The Time-Temperature-Transformation (TTT) diagram of a commercially available carbon fiber epoxy prepreg system has been developed by determining the gelation and vitrification behavior using small amplitude oscillatory shear and differential scanning calorimetry (DSC), respectively.

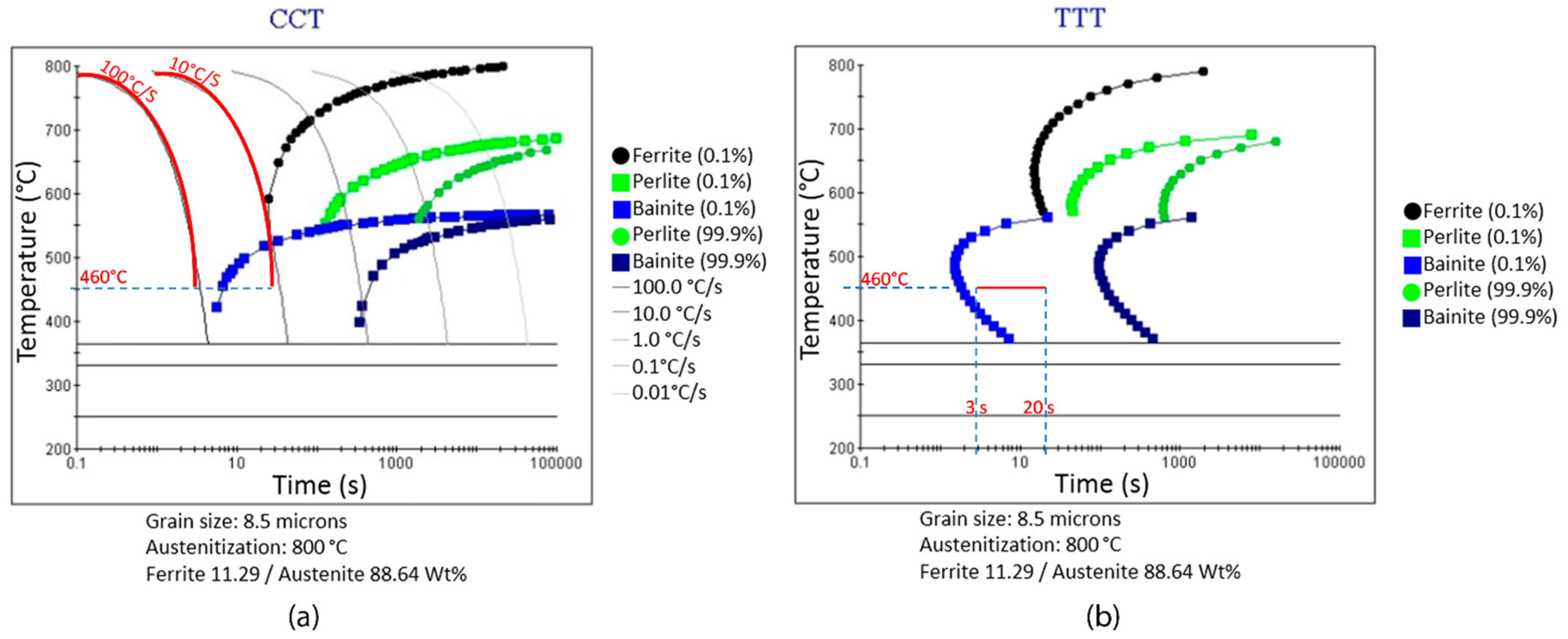

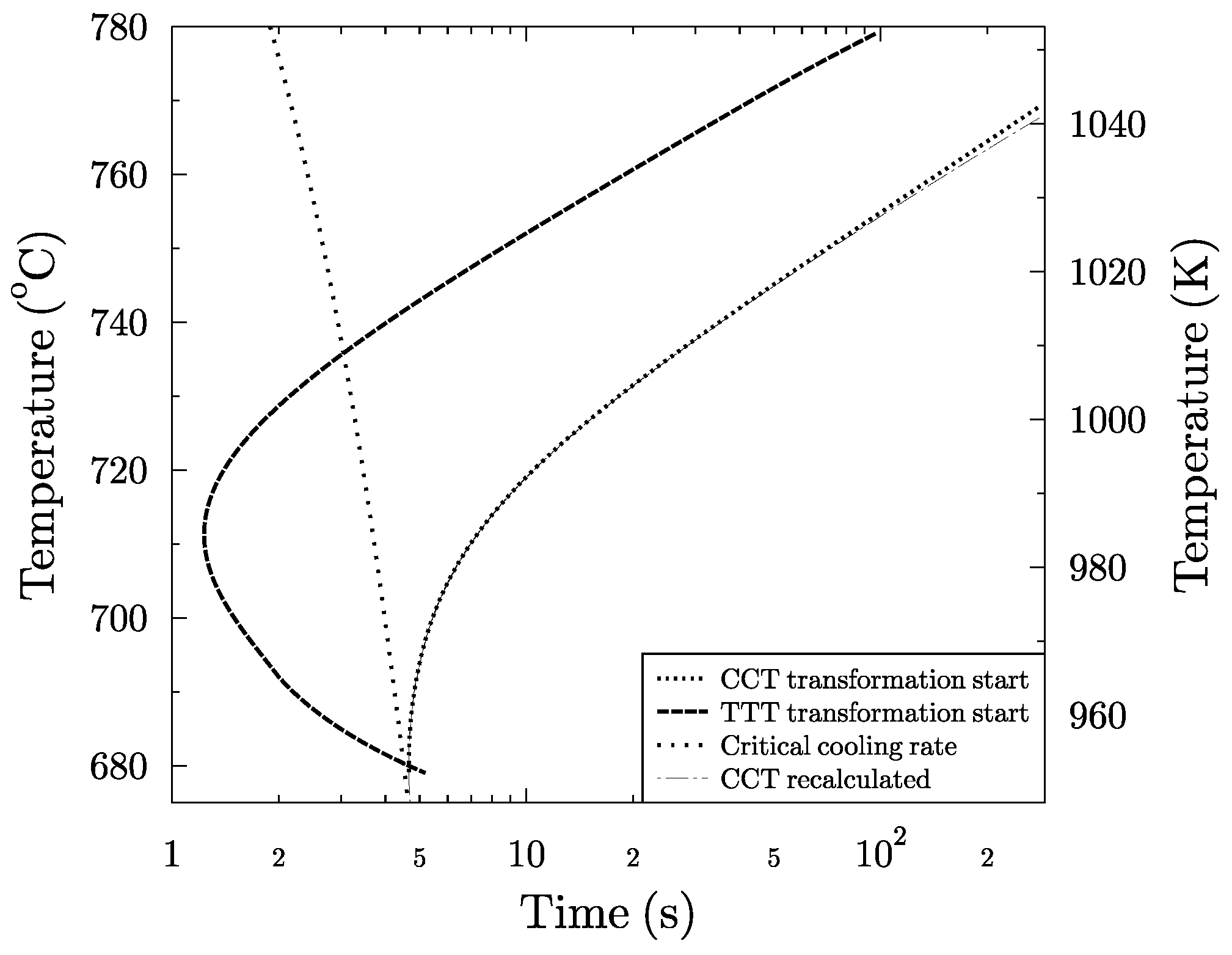

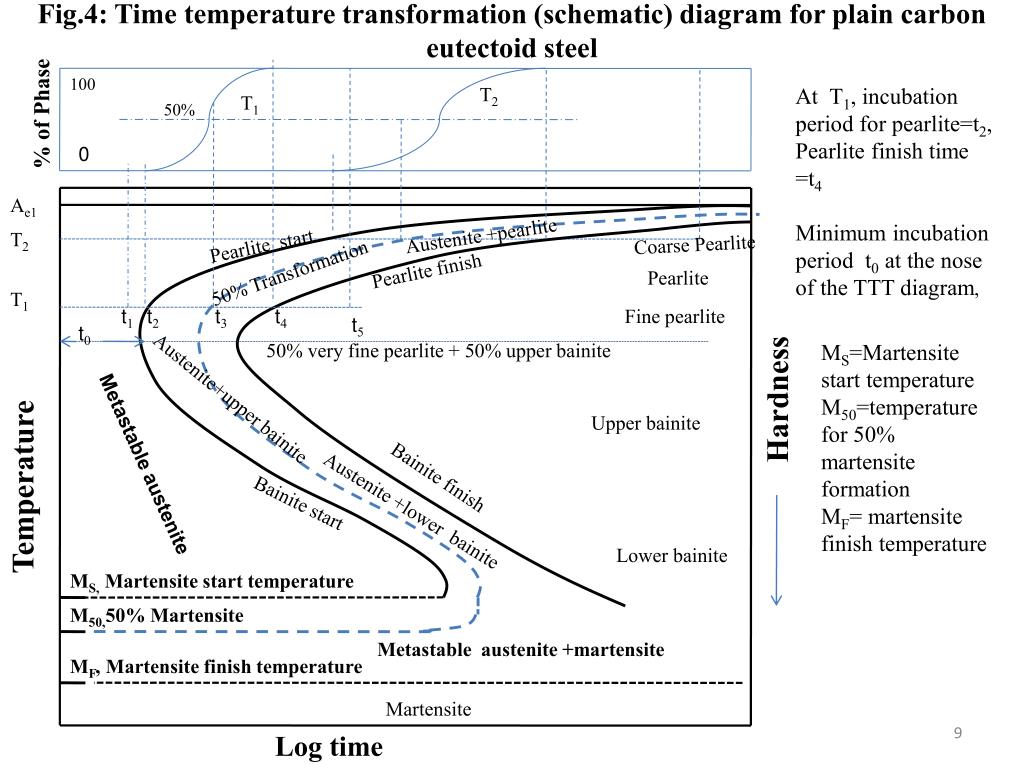

Time temperature transformation diagram. Transformation Diagrams, 1977. Reproduced by permission of ASM International, Materials Park, OH.] Generation of Isothermal Transformation Diagrams • The Fe-Fe3C system, for C0= 0.76 wt% C • A transformation temperature of 675 ºC. 100 50 0 1102 104 T = 675°C y, % transformed time (s) 400 500 600 700 110102 103 104 105 Austenite (stable) T ... time and temperature. TTT diagram shows the time required for transformation to various phases at constant temperature, and, therefore, gives a useful initial guide to likely transformations. In addition to the variations in the rate of transformation with temperature, there are variations in the structure of the transformation products also. Er. Time-Temperature-Transformation (TTT) diagram or S-curve refers to only one steel of a particular composition at a time, which applies to all carbon steels.This diagram is also called as C-curve isothermal (decomposition of austenite) diagram and Bain’s curve.The effect of time-temperature on the microstructure changes of steel can be shown by the TTT diagram. Time Temperature Transformation Diagrams. Time temperature transformation (TTT) diagrams, also known as isothermal transformation diagrams, predict phases and/or microstructure based on how the material is cooled. TTT diagrams have time on the x-axis and temperature on the y-axis. The lines on a TTT diagram represent points at which a material transforms from one phase or microstructure to ...

comprehensive diagram called the isothermal Time-Temperature-Transformation (TTT) cure diagram [3-5]. The isothermal TTT cure diagram is a useful framework for understanding and analyzing the behavior of thermoset resin systems during an isothermal cure process. The diagram was first Atlas of Time-Temperature Diagrams 3 Significance of the Isothermal Transformation Diagram When steel in the austenitic state is held at any constant temperature lower than the minimum at which its austenite is stable, it will in time transform. The course of isothermal transformation may be represent ... Time-Temperature-Transformation (TTT) Curves TTT diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. TTT diagram indicates a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved. Time Temperature Transformation (TTT) diagram. Course Name: Phase transformations and heat treatment . To describe and interpret time -temperature-transformation diagrams. Authors. Amol Subhedar (Under guidance of Prof. M.P. Gururajan) Education Level : UG. LO’s for prior viewing: NONE. Learning Objectives . After interacting with this Learning Object, the learner will be able to: • To ...

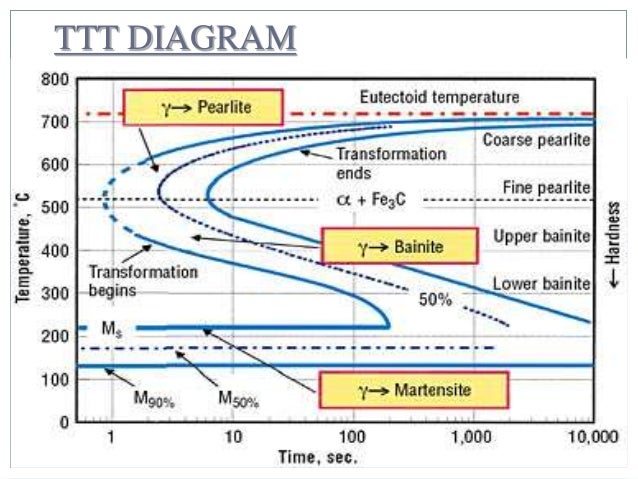

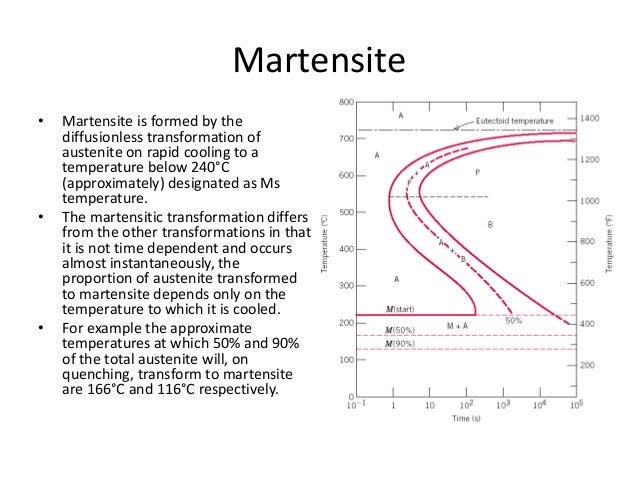

Explanation: TTT Diagram: The rate of phase transformation also depends upon the temperature.; Temperature-time-transformation diagram (TTT), also known as isothermal transformation curves, are useful in planning heat treatments. The complete isothermal transformation diagram for an iron-carbon alloy of eutectoid composition A (austenite), B (Bainite), M (Martensite), P (Pearlite) is below: Time - temperature - transformation (T-T-T) plots are also known as isothermal transformation diagrams. The sweeping curve going through the centre of the graph opposite is the transformation curve, which describes the extent of material which has changed through to pearlite. Time temperature-transformation diagram. 1. MM: 304 Heat treatment Topic: Transformation diagrams Compiled for T.E, Metallurgy by Engr. Muhammad Ali Siddiqui Lecturer Department of Metallurgical Engineering NED university of Engineering and technology Email: muetali@yahoo.com 1. 2. Time-Temperature-Transformation Diagram. An informative presentation of the silicone liquid rubber curing incorporating the degree of cure is the Time-Temperature-Transformation (TTT) diagram, developed by Enns and Gillham. It can be used to relate the material properties of thermosets, such as Silicone Liquid Rubber (LSR), as a function of ...

10.18 Using the isothermal transformation diagram for an iron-carbon alloy of eutectoid composition (Figure 10.22), specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time-temperature treatments. In

T (Time) T(Temperature) T(Transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. It is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. When austenite is cooled slowly to a temperature below LCT (Lower Critical Temperature), the ...

by R Manna · Cited by 9 — TTT diagram stands for “time-temperature-transformation” diagram. It is also called isothermal transformation diagram. Definition: TTT diagrams give the ...108 pages

Time-temperature-transformation (TTT) diagram

Time-Temperature-Transformation (TTT) Curves TTT diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. TTT diagram indicates a specific transformation starts and ends and it also shows what percentage of transformation of austenite at a particular temperature is achieved. The aims of TTT diagrams is determined type of structure for and portion ...

Metals Free Full Text Optimal Design Of Hot Dip Galvanized Dp Steels Via Artificial Neural Networks And Multi Objective Genetic Optimization Html

The relationships between the extents of conversion at gelation and at vitrification and the isothermal cure temperature form the basis of a theoretical model of the time-temperature-transformation (TTT) cure diagram, in which the times to gelation and to vitrification during isothermal cure versus temperature are predicted.

The time taken to 1% transformation to, say pearlite or bainite is considered as transformation start time and for 99% transformation represents transformation finish. On quenching in water austenite transforms to martensite. But below 230 C it appears that transformation is time independent, only function of temperature. Therefore after

The diagrams that illustrate the transformation of austenite as a function of time at a constant temperature is a TTT, or isothermal transformation (IT) diagram. In the simplest form (in plain carbon, or low alloy steels), these curves have a well-defined 'C' or 'S' shape.

Transformation Diagrams • There are two main types of transformation diagrams that are helpful in selecting the optimum steel and processing route to achieve a given set of properties. These are 1. Time-temperature transformation (TTT) diagrams 2. Continuous cooling transformation (CCT) diagrams.

Answer (1 of 4): 1.Continuous Cooling Transformation (CCT) Diagrams; In continuous cooling transformation from martensite to pearlite takes place at a range of temperature. CCT Diagram : -Stability of phases during continuous cooling of austenite. 2.TTT diagram stands for "time-temperature-tra...

a) Austenite. b) Pearlite. c) Bainite. d) Martensite. Answer: a. Clarification: At a temperature above 750 °C, the steel is in the form of austenite which is observed from a time temperature transformation diagram which shows the transformation time and temperature of transformation. 5.

This diagram shows the time, at a particular temperature, to start to transform and finish transforming to a transformation product such as ferrite, pearlite or bainite. This diagram can be thought of as a map which plots the transformations of austenite as a function of constant temperature and time.

Time-Temperature-Transformation Diagram. It is obvious that the equilibrium phase digram (Fig. 1) does not contain any information about phases such as bainite, martensite etc. This is because it represents equilibrium whereas the variety of transformation products have a range of deviations from the equilibrium state. The phase diagram for obvious reasons does not feature time. The kinetics ...

The Time-Temperature-Transformation (TTT) diagram of a commercially available carbon fiber epoxy prepreg system has been developed by determining the gelation and vitrification behavior using small amplitude oscillatory shear and differential scanning calorimetry (DSC), respectively.

Isothermal transformation diagrams (also known as time-temperature-transformation (TTT) diagrams) are plots of temperature versus time (usually on a logarithmic scale).They are generated from percentage transformation-vs time measurements, and are useful for understanding the transformations of an alloy steel at elevated temperatures.. An isothermal transformation diagram is only valid for one ...

Creation of time-temperature-transformation diagrams and what information we can extract from themLearning goals:- You describe the formation and occurrence ...

Metals Free Full Text Effects Of Chemical Composition And Austenite Deformation On The Onset Of Ferrite Formation For Arbitrary Cooling Paths Html

Figure 9 From Time Temperature Transformation Ttt Diagrams For Crystallization Of Metal Oxide Thin Films Semantic Scholar

First Principles Study Of The Cu Sub I X I Sub Ni Sub 1 I X I Sub Sub 3 Sub Sn Precipitations With Different Structures In Cu Ni Sn Alloys Xref Rid Cpb 27 8 086302 Fn1 Ref Type Fn Xref Fn Id Cpb 27 8 086302 Fn1 Label Label

File Time Temperature Transformation Diagram For M2 High Speed Tool Steel That Was Annealed Prior To Quenching Svg Wikimedia Commons

(171).jpg)

0 Response to "42 time temperature transformation diagram"

Post a Comment