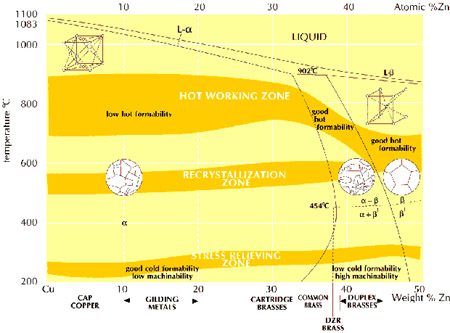

42 copper zinc phase diagram

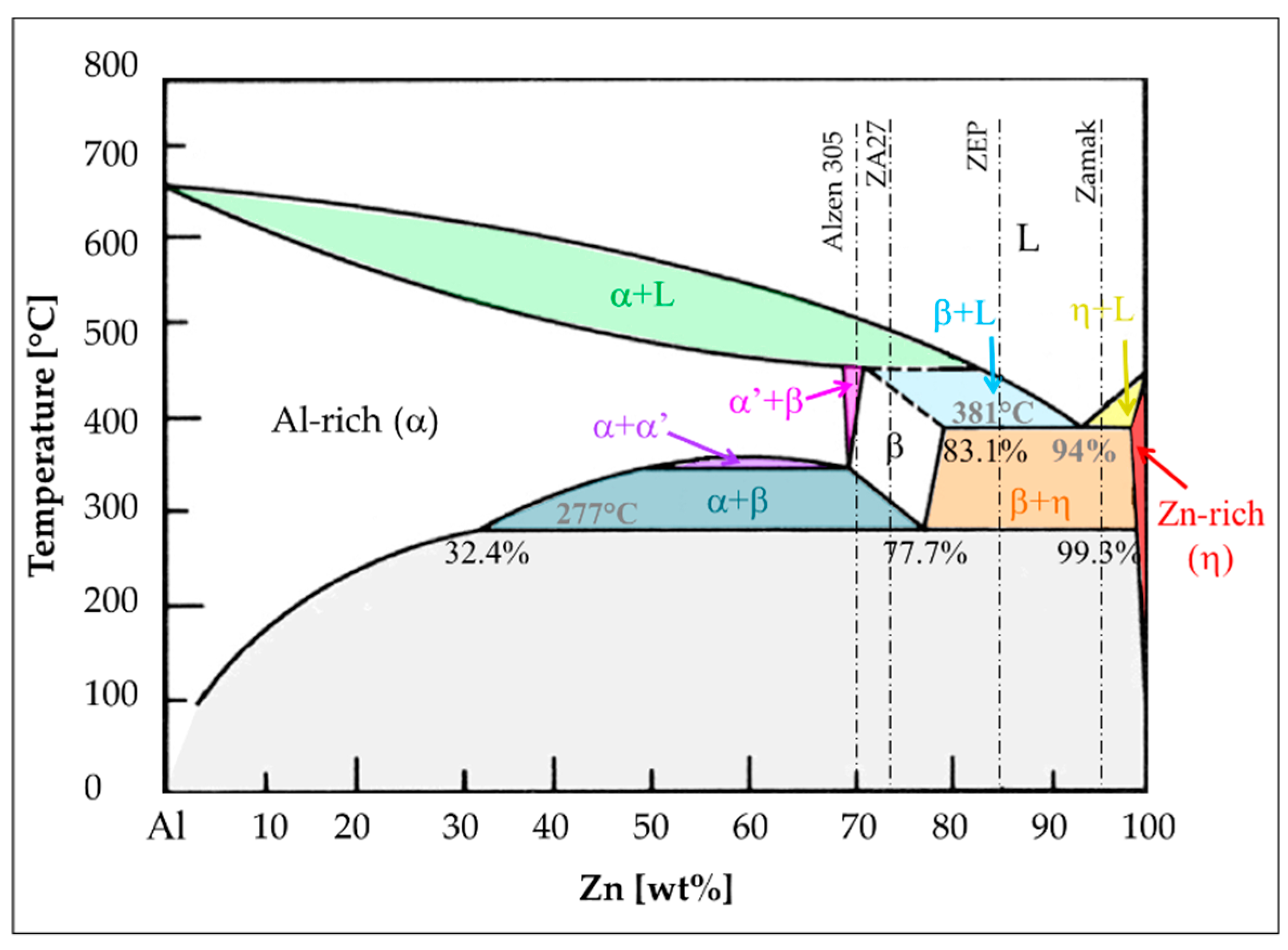

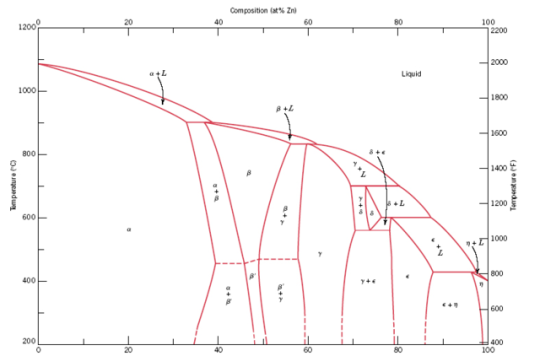

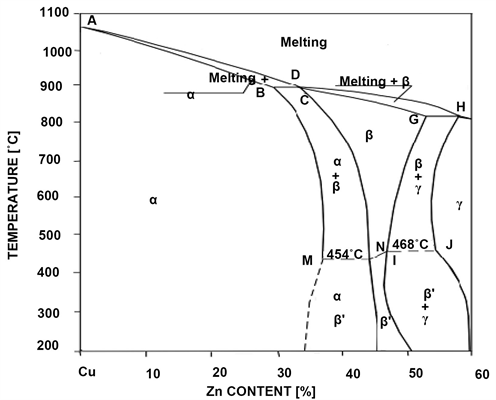

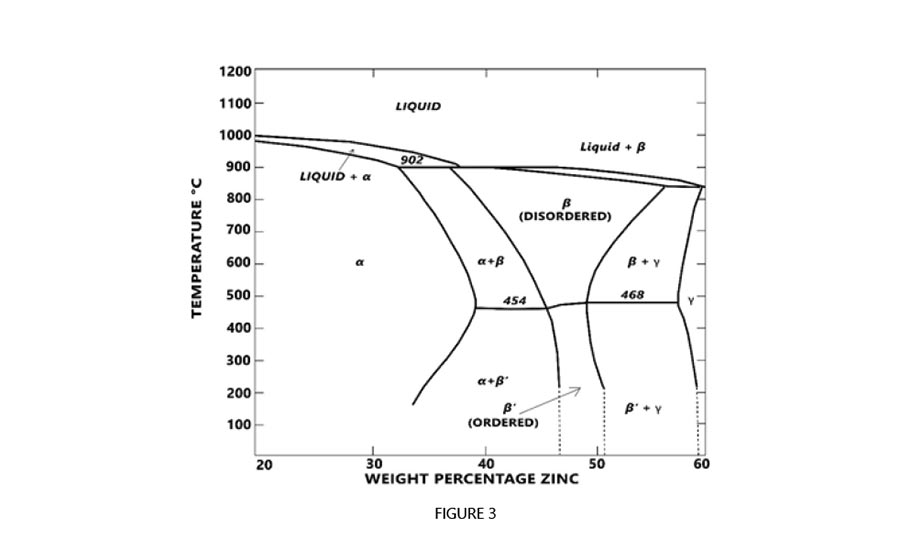

09mae324 - PD50 - Princeton University Phase Diagrams Brass · The Copper-Zincbinary phase diagram (brass) is another example of a complex phase diagram which shows many invariant reactions. · Two common alloy compositions are shown, Cartridge brass (red) which is Cu-30 wt % Zn, and Muntz metal (green) Cu-40 wt % Zn. From: Copper Zinc Phase diagram (I. Macleod after Lyman et al ... Download scientific diagram | Copper Zinc Phase diagram (I. Macleod after Lyman et al. 1973). from publication: Preliminary analysis of copper alloy fastenings from an unidentified shipwreck in ...

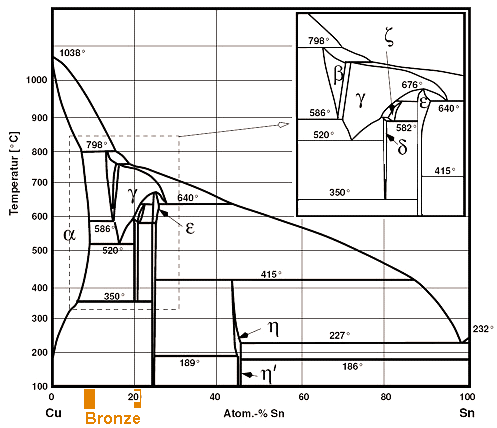

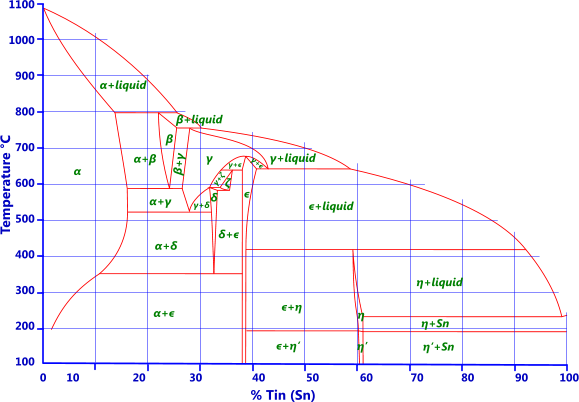

Copper based alloys - DoITPoMS Previous Next Copper based alloys. Brasses: Brasses are copper alloys with zinc, see the Cu-Zn phase diagram.. Alpha brass: From the copper-zinc phase diagram we can see the solid solubility of zinc in copper, for concentrations of zinc upto about 30 at.%, at equilibrium the alloy should be of a single phase.

Copper zinc phase diagram

Resources: Standards & Properties - Copper & Copper Alloy ... Alpha copper is the primary phase in cast alloys containing up to approximately 40% zinc. The beta phase,which is the high zinc phase, is the minor constituent filling in the areas between the alpha dendrites. The microstructure of brasses containing up to approximately 40% zinc consists of alpha dendrites with beta surrounding the dendrites. edu.rsc.org › experiments › the-determination-ofThe determination of copper in brass - RSC Education Brass forms an interesting subject for a discussion on the structure of metals and alloys. Copper metal has a face-centered cubic structure (fcc) while the structure of zinc is hexagonal. As zinc is added to copper it substitutes in the lattice to form a distorted fcc structure (zinc atoms are ca 13% larger than copper). engineeringinterviewquestions.com › mcqs-on-iron250+ TOP MCQs on Iron Carbon Phase Diagram and Answers The percentage of carbon at eutectic point in Fe-C phase diagram is? a) 2.1 b) 4.3 c) 0.83 ... 250+ TOP MCQs on Uses of Aluminium, Copper, Zinc and Iron and Answers ;

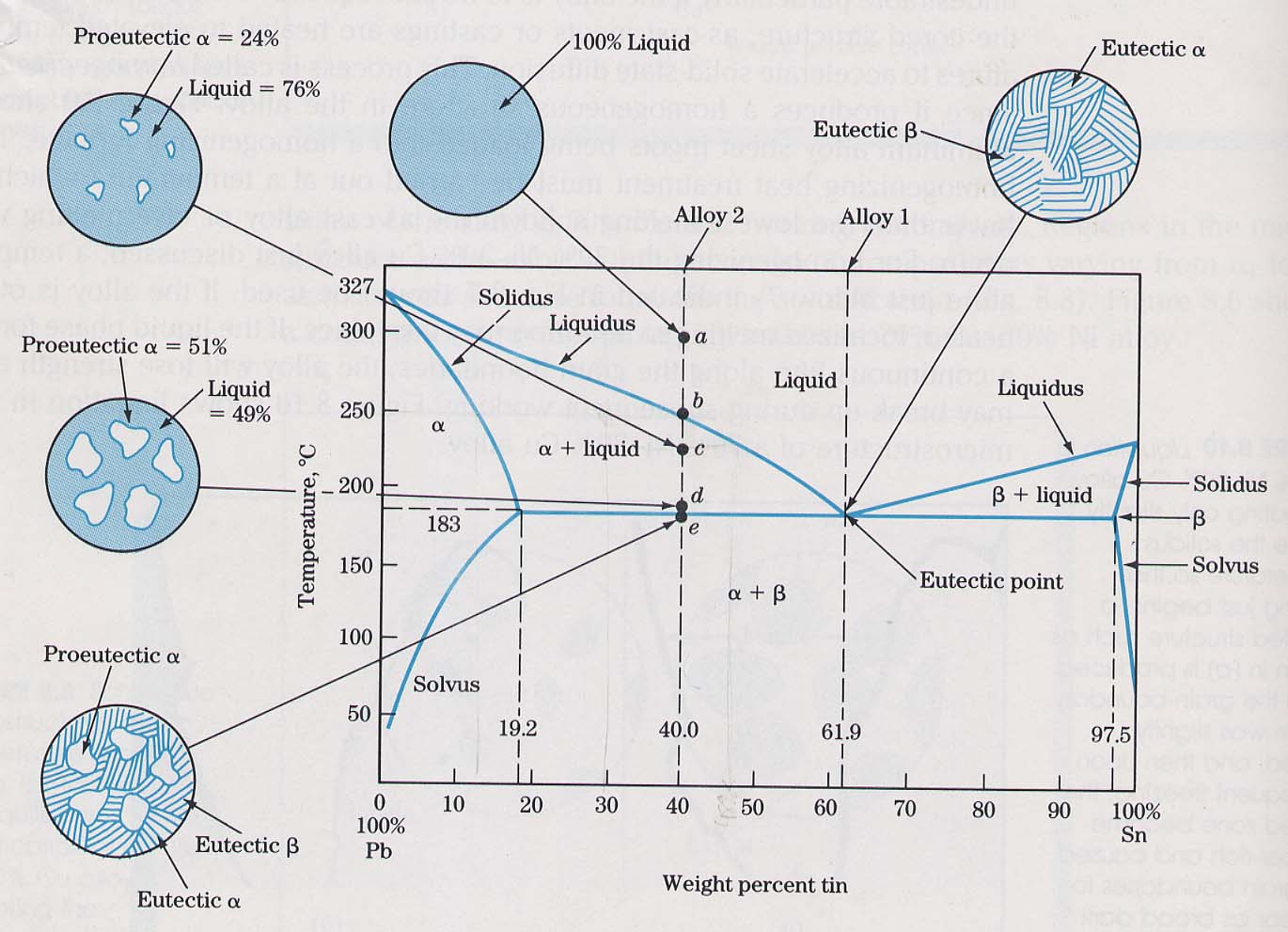

Copper zinc phase diagram. › resources › propertiesStandards & Properties: Metallurgy of Copper-Base Alloys This representation is called a phase diagram. The phase diagrams of some binary systems relevant to bronze show the behavior of alloying elements that typically results in one of the three cases mentioned previously. The copper-tin equilibrium phase diagram (Figure 3) illustrates Cases (1) and (2). Copper-Zinc Binary Alloy Phase Diagram (based on 1912 ... Diagram Type: binary phase diagram Concentration range: full composition; 0-100 at.% Zn. Temperature: 300.0 - 1100.0 °C Nature of investigation: experimental Source: ASM Alloy Phase Diagrams Center, 2007; data from Carpenter H.C.H., THE CRITICAL POINT AT 470 °C. IN COPPER-ZINC ALLOYS, J. Inst. Met., Vol. 7, 1912, p 70-104. Reviewed under the auspices of the Alloy Phase Diagram International ... Cu-Sn Phase Diagram & Computational Thermodynamics Phase Struktur-bericht Symbol Common Names Prototype Spacegroup Model *; Liquid: n/a: L: n/a: n/a (Cu,Sn) 1 Fcc: A1 (Cu) Cu: Fm-3m (Cu,Sn) 1 (Va) 1Bcc: A2 (beta Cu), beta: W: Im-3m (Cu,Sn) 1 (Va) 3Bct: A5 (Sn), (beta Sn) Copper Zinc Phase Diagram - [PPT Powerpoint] It is 19 wt% Mg-81 wt% Pb. Melting temperature of Mg2Pb 550 oC) Extensive solubility. of the phase diagrams. Eutectic transformation also called eutectic reaction. A eutectic reaction is an invariant reaction, and a eutectic point is also called an invariant point. the horizontal tie line at the eutectoid temperature is termed a eutectoid isotherm.

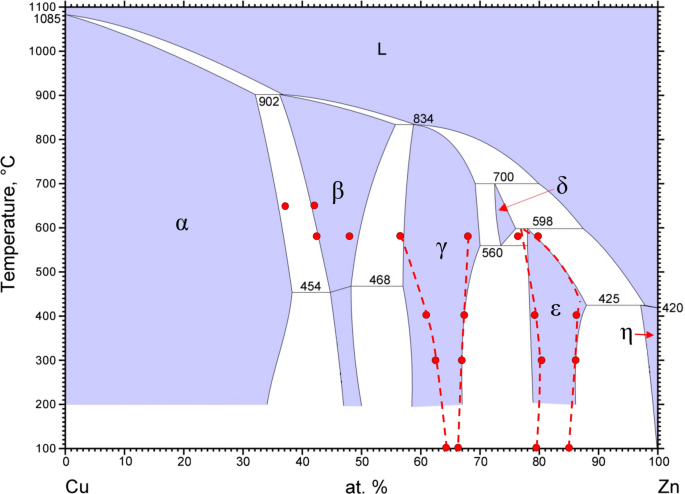

en.wikipedia.org › wiki › Voltaic_pileVoltaic pile - Wikipedia Schematic diagram of a copper–zinc voltaic pile. The copper and zinc discs were separated by cardboard or felt spacers soaked in salt water (the electrolyte). Volta's original piles contained an additional zinc disk at the bottom, and an additional copper disk at the top. These were later shown to be unnecessary Phase diagrams - Book chapter - IOPscience The copper-zinc system contains two terminal solid solutions, i.e. these are the extreme ends of phase diagram α and η, with four intermediate phases called β, γ, δ and ε. The β ' phase is termed an ordered solid solution, one in which the copper and zinc atoms are situated in a specific and ordered arrangement within each unit cell. Some Phase Diagrams - Technische Fakultät Phase diagram of copper (Cu) and zinc (Zn). The colored regions show typical brass compositions. The copper - zinc phase diagram is a bit simpler than the copper - tin phase diagram but still complex enough. There are all kinds of brass' but typically we are at the copper-rich side. PDF Lecture 19: 11.23.05 Binary phase diagrams A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points , C, 74 wt% Zn) and P (598 C, 78.6 wt% Zn), respectively. Figure by MIT OCW. Note that each single-phase field is separated from other single-phase fields by a two-phase field. Lecture 19 - Binary phase diagrams 6 of 16 11/23/05

PDF Intermediate Phases - University of São Paulo The copper-zinc phase diagram shown in Fig. 9.2 contains intermedi-ate phases with appreciable ranges of solid solubility. In this diagram, the copper-rich α solid solution and the zinc-rich η solid solution are the two terminal phases, and the four intermediate phases are β, γ, δ, and ε. The Copper-Zinc Alloys: The Brasses :: Total Materia Article Constitutional Diagram of the Copper-Zinc Alloys The addition of zinc to copper results in the formation of a series of solid solutions which, in accordance with usual practice, are referred to in order of diminishing copper content as the a, b, g, etc., constituents. The diagram may be summarized as follows: › metallurgy › metalsSolid Solution of Metals: With Diagram | Metallurgy Metals like silver and gold have a difference of 0.2%; nickel and copper of 2.7%, and show complete solid solubility. But zinc and copper have 4.2% difference with maximum solubility of 38.4 wt.% Zn. (other factors are less favourable); Cadmium in copper with 16.5% size difference shows a solid solubility of 1.7 wt.%. › applications › marineCopper-Nickel Alloys: Properties, Processing, Applications Zinc is a main constituent of copper-nickel-zinc alloys (previously ‘nickel silver’ or German silver), which are dealt with in a special DKI information booklet. In contrast, the zinc content of Cu-Ni alloys is restricted to 1% max. Zinc-free alloys are required as materials for fittings in electron tubes to avoid zinc vaporisation.

PPT Chapter 9 Commercial brasses are copper-rich copper-zinc alloys. For example, cartridge brass is 70 wt% copper-30 wt% zinc 15 16 The magnesium-lead phase diagram: like two simple eutectic diagrams joined back to back Intermetallic compound (with distinct chemical formula), NOT a solid solution.

PDF Chapter Phase Diagrams - Uttar Pradesh Textile Technology ... phase diagrams for pure materials; (3) the interpretation of phase diagrams; (4) ... For example, in a copper-zinc brass, the components are Cu and Zn.Solute and sol-vent, which are also common terms, were defined in Section 4.3.Another term used in this context is system,which has two meanings.

Copper Zinc Phase Diagram | PDF The copper-zinc phase diagram: Terminal and Intermediate Solid Solutions. Terminal solid solutions. intermediate solid solutions. Commercial brasses are copper-rich copper-zinc alloys. For example, cartridge brass is 70 wt% copper-30 wt% zinc Chapter 9- 15 The magnesium-lead phase diagram: like two simple eutectic diagrams joined back to back Melting temperature of Mg2Pb 550 oC)

en.wikipedia.org › wiki › Copper(I)_iodideCopper(I) iodide - Wikipedia Copper(I) iodide, like most binary (containing only two elements) metal halides, is an inorganic polymer. It has a rich phase diagram, meaning that it exists in several crystalline forms. It adopts a zinc blende structure below 390 °C (γ-CuI), a wurtzite structure between 390 and 440 °C (β-CuI), and a rock salt structure above 440 °C (α-CuI).

Phase diagram of the copper-zinc system [17]. | Download ... Download scientific diagram | Phase diagram of the copper-zinc system [17]. from publication: Cu-Zn powders as potential Cr(VI) adsorbents for drinking water | This work examines the possibility ...

Solved For the Copper-Zinc system, Print out the phase ... For the Copper-Zinc system, Print out the phase diagram and show all work for the following questions. No phase diagram will result in no credit for this question. Assume a basis of 10 kilograms of starting material to give me the final mass amounts. a) At 55%wt Zinc and 600oC, tell me what phases are present, what the mass amounts of each ...

Phase Diagram for Cu-Zn - DoITPoMS Phase Diagram for Cu-Zn. Move the mouse over the phase diagram to view temperature and composition at any point. View micrographs for the Cu-Zn system. List all systems with phase diagrams. 2004-2022 University of Cambridge. Except where otherwise noted, content is licensed under a

Zinc phase diagrams - Big Chemical Encyclopedia Figure 9.21 A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points, labeled E (560°C, 74 wt% Zn) and P (598°C, 78.6 wt% Zn), respectively. The most common copper alloys are the brasses, for whieh zine, as a snbstitntional impurity, is the predominant alloying element.

Based on the copper-zinc (Cu-Zn) phase diagram (Cu-Zn ... The Copper - Zinc Phase Diagram (37 points) Composition tots Zn) 1200 100 72200 2000 Loud 1000 1600 Temperature (°C) Temperature (F) 1000 800 400 400 100 60 Cu Composition (wt% Zn) The Cu - Zn phase diagram (from Binary Aloy Phase Diagrams, TB...

PDF Chapter 6 Alloys with a High Content of Zinc Alloys with a High Content of Zinc This chapter considers the phase composition of alloys that contain zinc and magnesium as obligatory components. Many of these alloys also contain copper; therefore, the Al-Mg-Zn and Al-Cu-Mg-Zn phase diagrams are basic for this group of alloys, which includes mainly wrought alloys of the 7XXX series, e.g. high-

engineeringinterviewquestions.com › mcqs-on-iron250+ TOP MCQs on Iron Carbon Phase Diagram and Answers The percentage of carbon at eutectic point in Fe-C phase diagram is? a) 2.1 b) 4.3 c) 0.83 ... 250+ TOP MCQs on Uses of Aluminium, Copper, Zinc and Iron and Answers ;

edu.rsc.org › experiments › the-determination-ofThe determination of copper in brass - RSC Education Brass forms an interesting subject for a discussion on the structure of metals and alloys. Copper metal has a face-centered cubic structure (fcc) while the structure of zinc is hexagonal. As zinc is added to copper it substitutes in the lattice to form a distorted fcc structure (zinc atoms are ca 13% larger than copper).

Resources: Standards & Properties - Copper & Copper Alloy ... Alpha copper is the primary phase in cast alloys containing up to approximately 40% zinc. The beta phase,which is the high zinc phase, is the minor constituent filling in the areas between the alpha dendrites. The microstructure of brasses containing up to approximately 40% zinc consists of alpha dendrites with beta surrounding the dendrites.

![2. The equilibrium Cu-Zn phase diagram. [61] | Download ...](https://www.researchgate.net/profile/Zhou-Peng-7/publication/322748528/figure/fig4/AS:587563039461383@1517097353986/The-equilibrium-Cu-Zn-phase-diagram-61.png)

![Chapter 9] Use the partial phase diagram below to determine ...](https://img.homeworklib.com/images/6cc752ea-06cd-4406-952e-8ec36eded450.png?x-oss-process=image/resize,w_560)

.jpg)

0 Response to "42 copper zinc phase diagram"

Post a Comment