41 steam boiler piping diagram

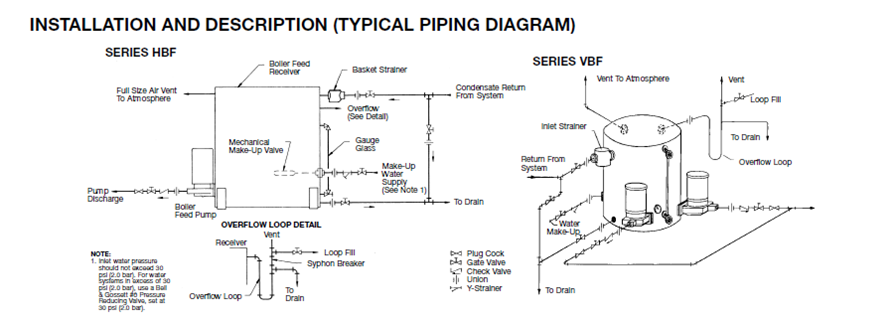

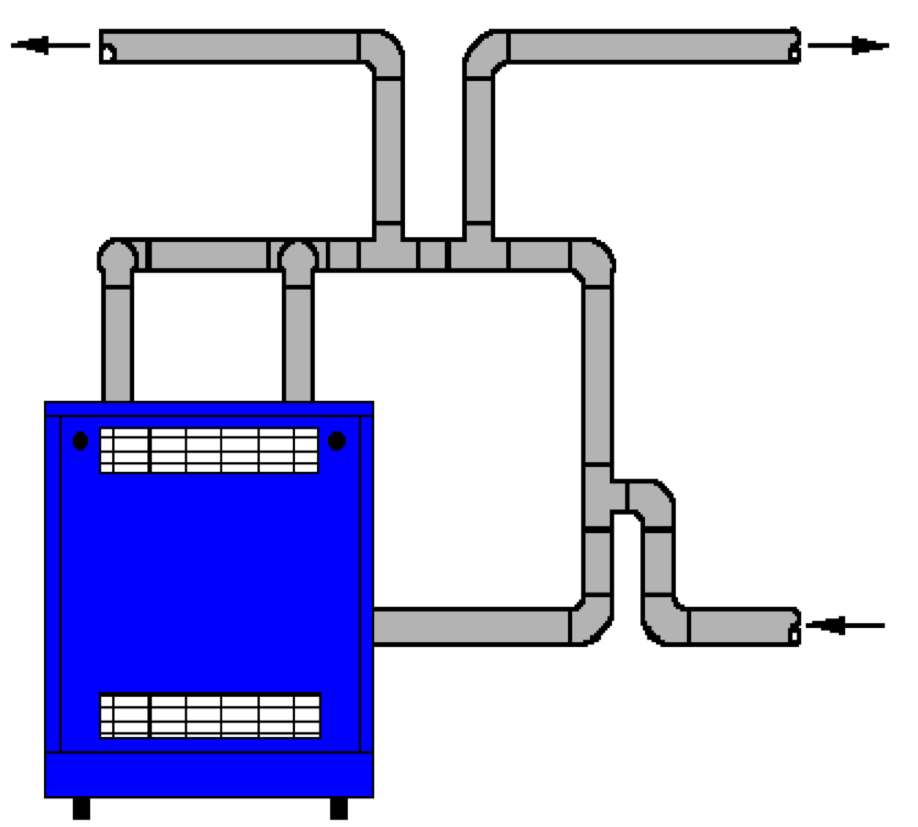

Piping Diagram - Cemline. CEMLINE® has made a series of typical piping arrangements for the Model Series: USG High Temperature Hot Water Fired Steam Generator - PDF or DWG. A Hartford Loop is an arrangement of piping between a steam boiler's header and its gravity-return piping. The end of the header drops vertically below the. Pipe sizing – one pipe counterflow systems a) Mains are sized one size larger than they would be for parallel flow piping. This allows room for the condensate to flow along the bottom of the pipe. F. PARALLEL FLOW SYSTEMS 1. One pipe parallel flow with wet return a) Operation b) Pipe Sizing 2. One pipe parallel flow with dry return a ...

Steam Boiler Piping Diagram. Steamhead Member Posts: 14,816. September 2005. in THE MAIN WALL. the "one-pipe" or "two-pipe" parts of the system occur after the steam main leaves the boiler's header. So it wouldn't be shown on that Columbia/Utica gas steamer diagram. What type of boiler and system do you have?

Steam boiler piping diagram

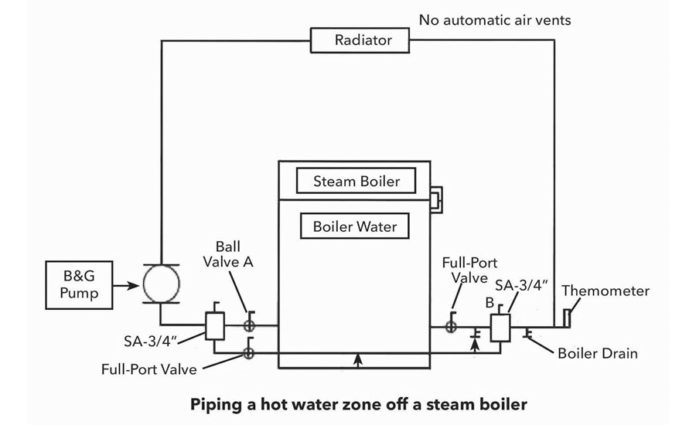

2 Part number 550-141-829/0316 GOLD SGO OIL-FIRED NATURAL DRAFT STEAM BOILER — SERIES 3 — Boiler Manual HOMEOWNER and SERVICE TECHNICIAN — read and follow completely. The following defined terms are used throughout this manual to bring attention to the presence of hazards Steam Boiler Piping Diagram. Sharing. Published: February 20, 2018. Categories: Steam. Steam boiler piping: The right way to pipe takeoffs from a header. 13. Wire the tank or system/pipe sensor connected to the DHW sensor terminals on the follower boiler addressed as #1. 14. The system/pipe sensor must be placed on common piping to the tank, as close to the tank as possible. 15. The system/pipe sensor is wired to the system sensor terminals on the master boiler.

Steam boiler piping diagram. Piping Diagram - Series 64™ Near Boiler Piping Diagram - 64-09 through 64-12. Dan Holohan explains best practices for how to pipe a steam heating boiler. Learn more at www.heatinghelp.com.Want to be an expert? Read Dan Holohan's book T... Steam lines should ideally be arranged to fall in the direction of flow, at not less than 100 mm per 10 m of pipe (1:100).This slope will ensure that gravity (and the flow of steam), will assist in moving the condensate towards drain points so that the condensate may be safely and effectively removed (see Fig. 15.4).Any steam lines rising in the direction of flow should slope at not less than ... The expansion tank must be properly. As drawn in the diagram, to charge the tank from the primary loop. 2. tanks ( where the hot water enters) and going to the Burnham boiler. ma servicing a gas steam boiler burnham piping diagram furnace ac and plumbing repair in. burnham steam boiler gas manual. steam boiler wiring diagram.

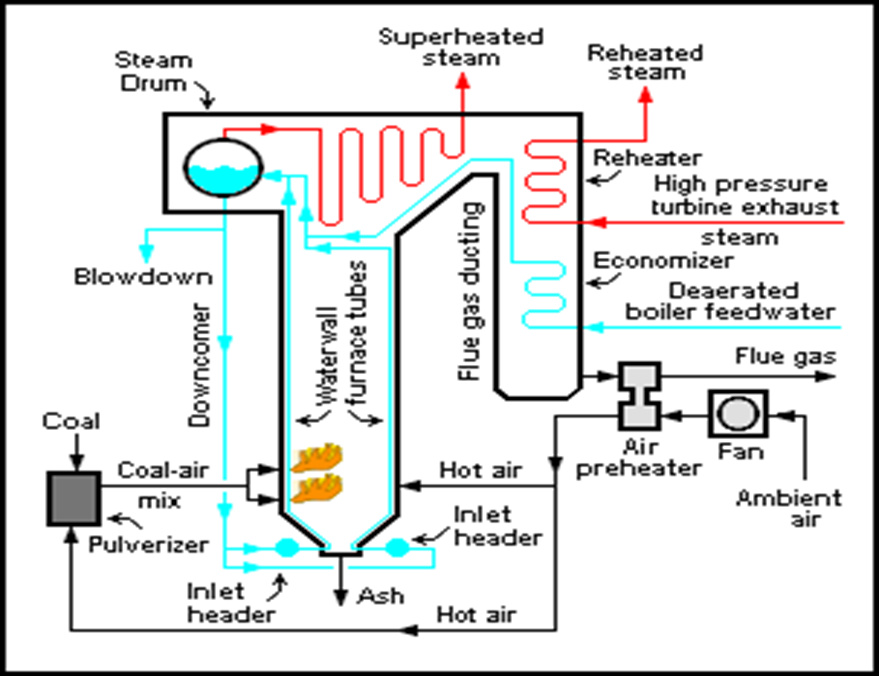

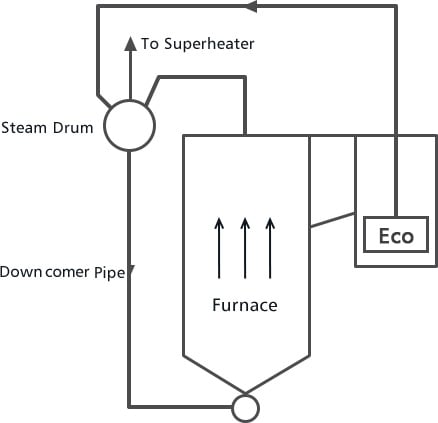

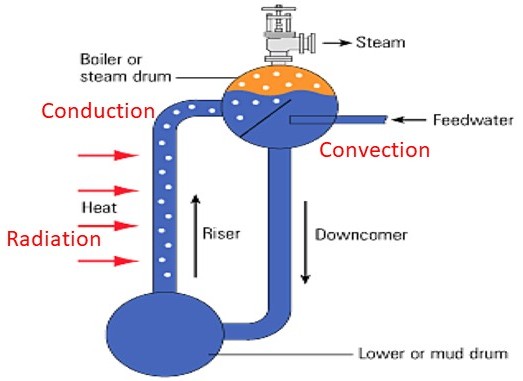

The correct way to install a PRV is shown in the above diagram. There must be a minimum distance between the PRV and sensing point, and the control line must slope down to the pipe – NOT the PRV, so that condensate will drain back to the steam line where it will be removed by a steam trap. Dec 13, 2017 · Steam Boiler Diagram With Parts for Dummy’s. Below is a typical steam boiler diagram for dummy’s to understand with name of each component or boiler part. First of all you should understand that there are many types and nomenclature of boilers. For example steam boiler, combi boiler, vaillant boiler, hot water boiler, gas boiler, electric boiler, weil mclain boiler, condensing boiler, oil boiler, burnham boilers, central boiler, lochinvar boiler, water tube boiler, system boiler, central ... the discharge pipe between such valve and the atmosphere. Doing so can cause an accidental explosion from overpressure. The discharge from the safety relief valve shall be so arranged that there will be no danger of scalding personnel or damage to equipment. Provisions should be made to properly drain safety relief valve discharge piping. Standard Steam Boiler Plant Piping Diagram Author: Department of Veterans Affairs, Office of Construction and Facilities Management, Facilities Standards Service Subject: Standard Details Created Date: 10/7/2020 2:22:24 PM

Burnham Steam Boiler Piping Diagram Jan 7, In October, my 30+ year old steam gas boiler was replaced (had corrosion and leaking gas) with a Burnham Independence Steam boiler. It is common and acceptable practice to install these boilers in lower pressure systems, below the boiler MAWP. Therefore, Burnham offers safety relief valves set at or ... While a lot of attention is paid to efficient boilers and innovative radiators, the design of the piping system is often what makes or breaks a hydronic heat system. A good piping system can be the difference between a noisy, uncomfortable, energy-wasteful system, and one that brings even comfort to all the rooms in a house. Sizing a Steam Boiler Many Steam boilers are undersized for the actual NET load Determine the BTU required for the heat load Add losses for the piping, distribution, etc. Correct for the operating pressure of the boiler Correct for the feedwater temperature of the boiler 3. A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream of all closely spaced tees. 4. The minimum pipe size for connecting a Super Stor water heater is 1 inch. 5. The minimum pipe size for connecting a Munchkin boiler shall be 1.25 inches and 2 inches for the 399M. 6. All pumps are shown with isolation flanges.

VENT PIPING— A. Vent piping installation must be in accordance with ANSI Z223.1-latest edition, National Fuel Gas Code, Part 7, Venting of Equipment. Other local codes may also apply and must be followed. B. Boiler vent pipe must be the full diameter of the boiler draft hood outlet. See dimensions, page 2. If a vent damper is

performance of a replacement steam boiler and should always be considered as part of the boiler installation. Always be sure to include clean-out and skimming tees in the near boiler piping. These "Tees" are necessary for proper cleaning and servicing of the boiler. • For further piping information refer to the I=B=R

What Is Boiler Types Of Boiler Steam Boiler How Boiler Work Boiler Operation Boilers Diagram How Does A Steam Boiler Work

Product Drawings. Piping Diagram. Technical Papers. 3D-Drawings. Spec Sheets. CEMLINE® has made a series of typical piping arrangements for the Model Series: SEH, SSH, SWH, and USG. These drawings are in .DWG format or Adobe®Acrobat® (PDF) format. The Acrobat Reader is available free from Adobe. Note: Select the model and click on the ...

Low Pressure Steam Heating System Application And Selection Guide For Residential And Commercial Systems Xylem Indonesia

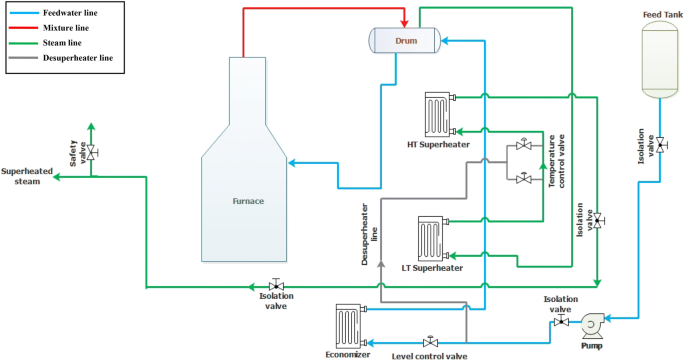

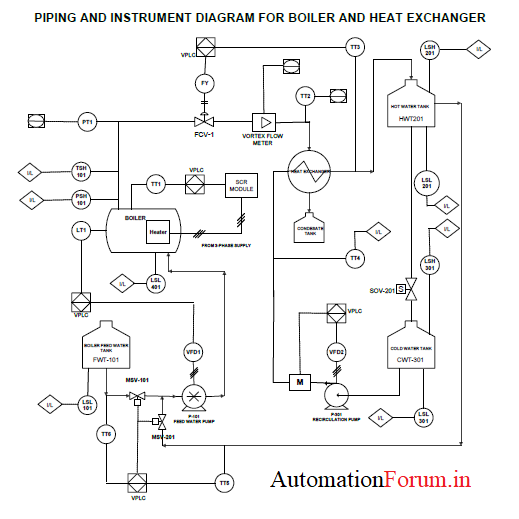

Design of Boilers and Power Piping The Boiler Manufacturer has to define where the change from Boiler to Boiler External Piping and Boiler External Piping to Non‐Boiler External Piping exists. This is typically done using Piping and Instrumentation Diagrams (P&ID's) or drawings

piping must be the same size as the relief valve discharge opening. Avoid over-tightening as this can distort valve seats. All piping from relief valve must be independently supported with no weight carried by the valve. 1.4.5 BLOWDOWN CONNECTION Blowdown valve(s) must be full size of the connection on the boiler. Steam boilers 15 psig and

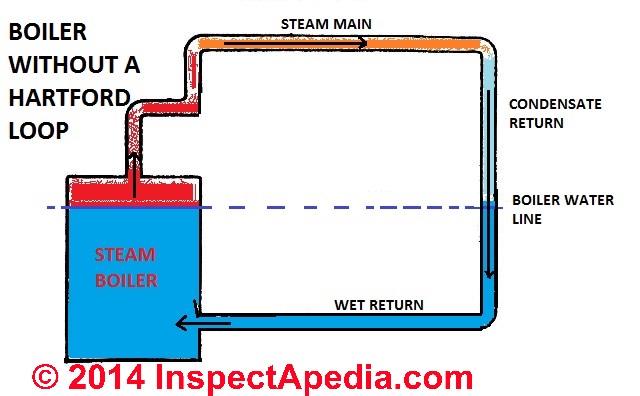

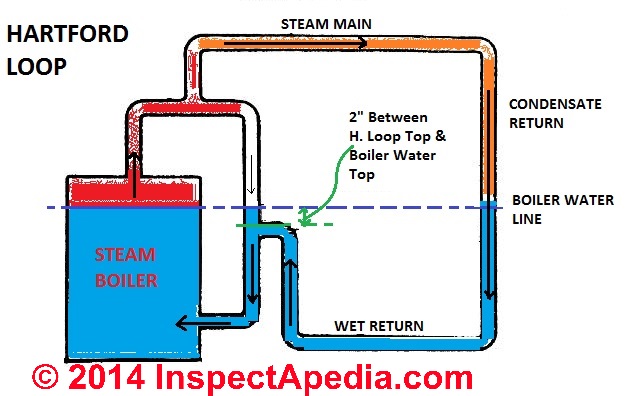

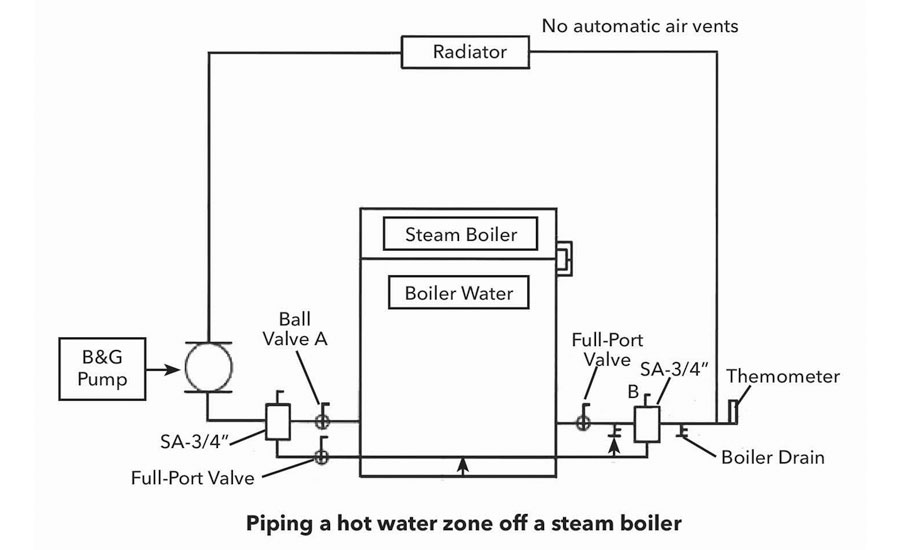

The primary component of a Hartford loop diagram is the location of a Hartford loop top and its distance from the boiler water top. Standard Hartford loop diagrams generally place the top of the loop 2 inches below the steam boiler's water line. hartford loop steam piping diagram is among the photos we discovered on the net from reputable sources.

application type diagram see installation manual for complete instructions. install in accordance with all local codes. typical piping for conventional single boiler installation lb-500, lb-750, lb-1000 • safety relief valve setting should not exceed pressure rating of any component in the system. • piping should conform to local codes.

System Diagrams Radiant Heat Multi Zone In-Floor 71 73 75 80 86 102 76 67 65 Forced Air vs. Radiant In-Floor Insulation Closed-cell Polystyrene Thermal Insulation OUT IN Greenhouse Heating Options Radiant PEX piping under the table Forced Air Return Supply When using mesh style tables - PEX piping must be protected from UV rays. 4 mil. black ...

WIRING DIAGRAMS. Most of the wiring diagrams are for natural gas powered steam boilers. Wiring diagrams for oil burning and water boilers are noted. CT 6, 10, 15 and 25 boiler wiring diagram. CT 6 and 25 boiler wiring diagram. CT 35 and 50 boiler wiring diagram. HRT 20 and 30 boiler wiring diagram. Keystone series boiler wiring diagram.

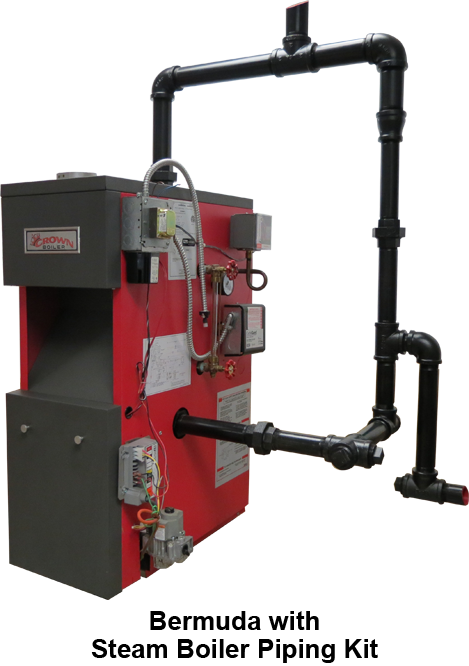

The Velocity Boiler Works Steam Boiler Piping Kit is a more convenient way to pipe steam boilers during an installation. The kits work with both oil and gas models and are available for the Bermuda, Kingston, and Freeport 2 FSZ boilers.. Kitted to allow you to pipe the near boiler piping as recommended in the manual, this will guarantee you go to the job prepared and won’t waste time making ...

Equip all boilers in gravity return systems with Hartford Loop as shown in Figure 5a and 5b page 9. 7. Piping vertical risers from boiler to header, risers must be minimum of 24" high above water line.. 8. Steam riser(s) and header shall be 2" pipe size. 9. Equalizer line shall be minimum 1-1/2" pipe size. 10.

The Hartford Loop: this article gives a defnition of the Hartford Loop used on steam heating systems, explains why the Hartford Loop is necessary to protect against steam boiler damage, and gives a bit of the history of the development of the Hartford loop. We include sketches and photographs of the Hartford Loop piping arrangement on steam boilers and list inspection & defect points of interest.

The piping must have pitch or fall to help the steam rise, and more importantly, to allow the condensate to flow back to the boiler. Level piping holds water, so it must have fallen. Also, a Hartford Loop is required to connect the supply and return.

13. Wire the tank or system/pipe sensor connected to the DHW sensor terminals on the follower boiler addressed as #1. 14. The system/pipe sensor must be placed on common piping to the tank, as close to the tank as possible. 15. The system/pipe sensor is wired to the system sensor terminals on the master boiler.

Steam Boiler Piping Diagram. Sharing. Published: February 20, 2018. Categories: Steam. Steam boiler piping: The right way to pipe takeoffs from a header.

2 Part number 550-141-829/0316 GOLD SGO OIL-FIRED NATURAL DRAFT STEAM BOILER — SERIES 3 — Boiler Manual HOMEOWNER and SERVICE TECHNICIAN — read and follow completely. The following defined terms are used throughout this manual to bring attention to the presence of hazards

P Id Diagram For Boiler Industrial Automation Industrial Automation Plc Programming Scada Pid Control System

Vertical 300 Kg Electric Steam Boiler 216kw Input Power Iso9001 Standard For Sale Boiler Spare Parts Manufacturer From China 108055841

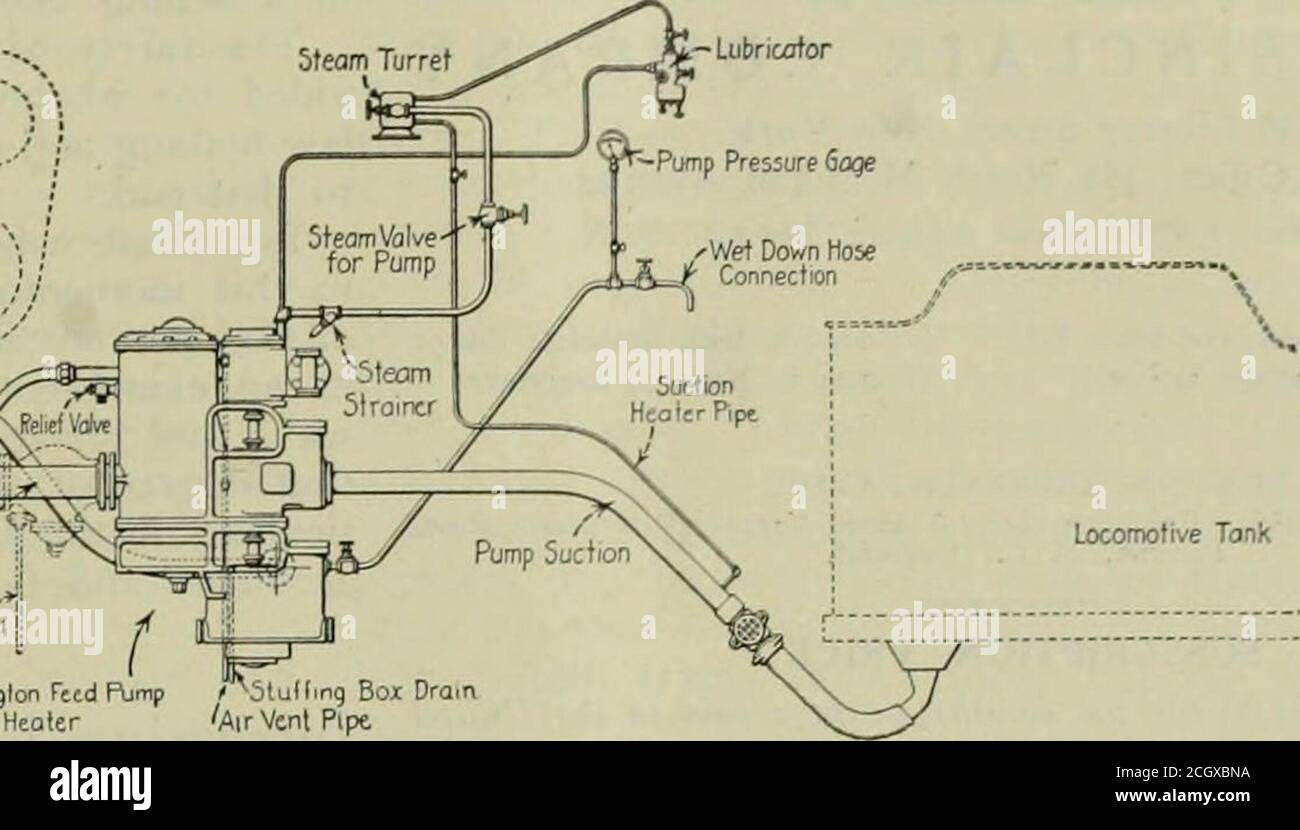

Railway And Locomotive Engineering A Practical Journal Of Railway Motive Power And Rolling Stock 7 5team To Heater Yt T B Fti Expansion Oil Separator 1

0 Response to "41 steam boiler piping diagram"

Post a Comment