37 wabco air dryer diagram

Used 2005 Peterbilt 385, AIR DRYER, Make: Bendix, W/ governor, WABCO FILTER: 432 410 020 Text Seller About the Part. Stablished in Spring Valley, CA since 1980 Global Air, Inc. +Peterbilt Air Conditioning Diagram. 575. Kenworth Heating and Air Conditioning Parts. View as Grid List. and finally we upload it on our website.

21.12.2021 · Kenworth 8 Bag Air Suspension Diagram Free Diagram For January 1st, 2021 - This is a image galleries about kenworth 8 bag air ride suspensionyou can also find other images like wiring diagram parts diagram replacement parts components airglide 100 suspensions air suspension height control valves st louis truck driveshafts we concerted it to the ...

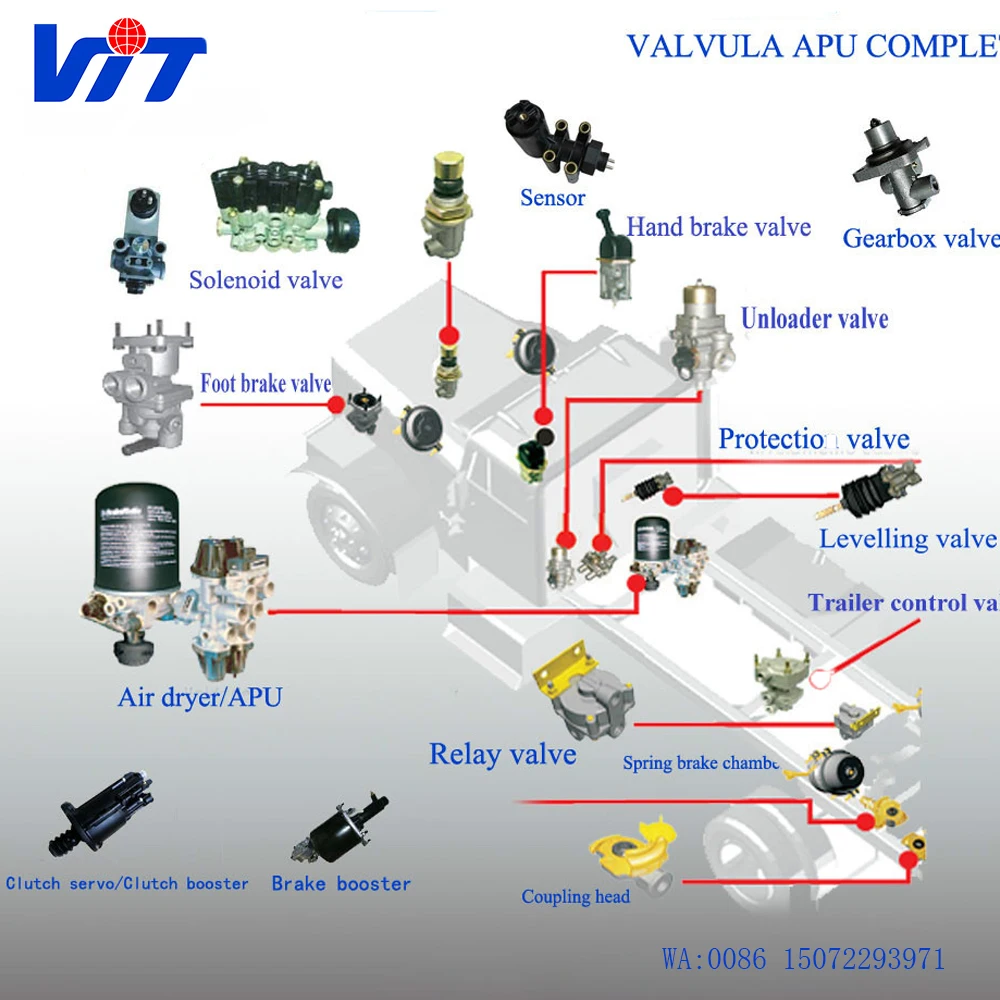

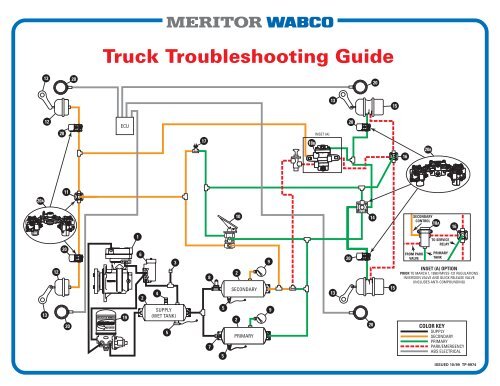

The purpose of an air brake system on heavy duty vehicles is to convert air pressure to mechanical energy to activate the foundation brakes. Federal Motor Vehicle Safety Standard 121 dictates how this is to be done for over-the-road vehicles. The purpose of this book is to help you construct Meritor WABCO Truck and Tractor air systems.

Wabco air dryer diagram

WABCO websites use cookies and other tracking technologies to improve your browsing experience and provide you with services available on the website. To find out more about which cookies we use and how you can block them, please read here.

In this article, we consider the seventh-generation Ford F-650 / F-750, produced from 2001 to 2015. Here you will find fuse box diagrams of Ford F-650 and F-750 2004, 2005, 2006, 2008 and 2011, get information about the location of the fuse panels inside the car, and learn about the assignment of each fuse (fuse layout) and relay.

wiring diagram index name description page aa power distribution frc 1/2 3 ... ea abs control wabco 41 eb suspension ecu 6x2 42 ... ed abs control bendix ecs 44 fa air dryer/heated drain valve 45 fd chassis solenoids 1/2 46 fe chassis solenoids 2/2 47 ga lighting control 1/2 48 gb lighting control 2/2 49 ...

Wabco air dryer diagram.

There's a few duplicate grounds. Advantage: Van Hool. Step on the brake pedal and put the bus into gear. AIR DRYER ASSEMBLY - REPLACES MERITOR WABCO SYSTEM SAVER 1200 SERIES R955205. The unit also comes with key switch, low air buzzer and light. I had the compressor head replaced, then started it up.

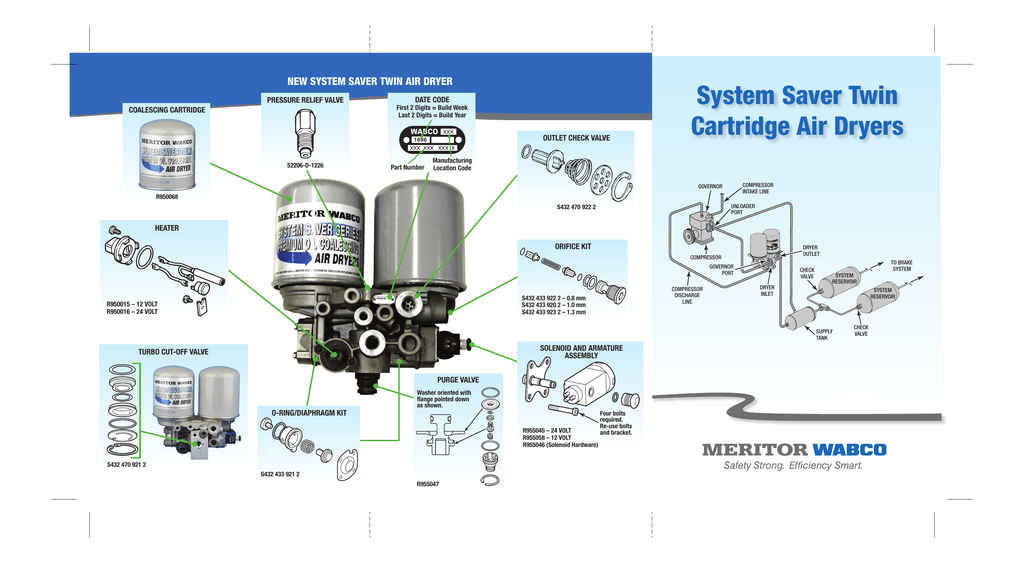

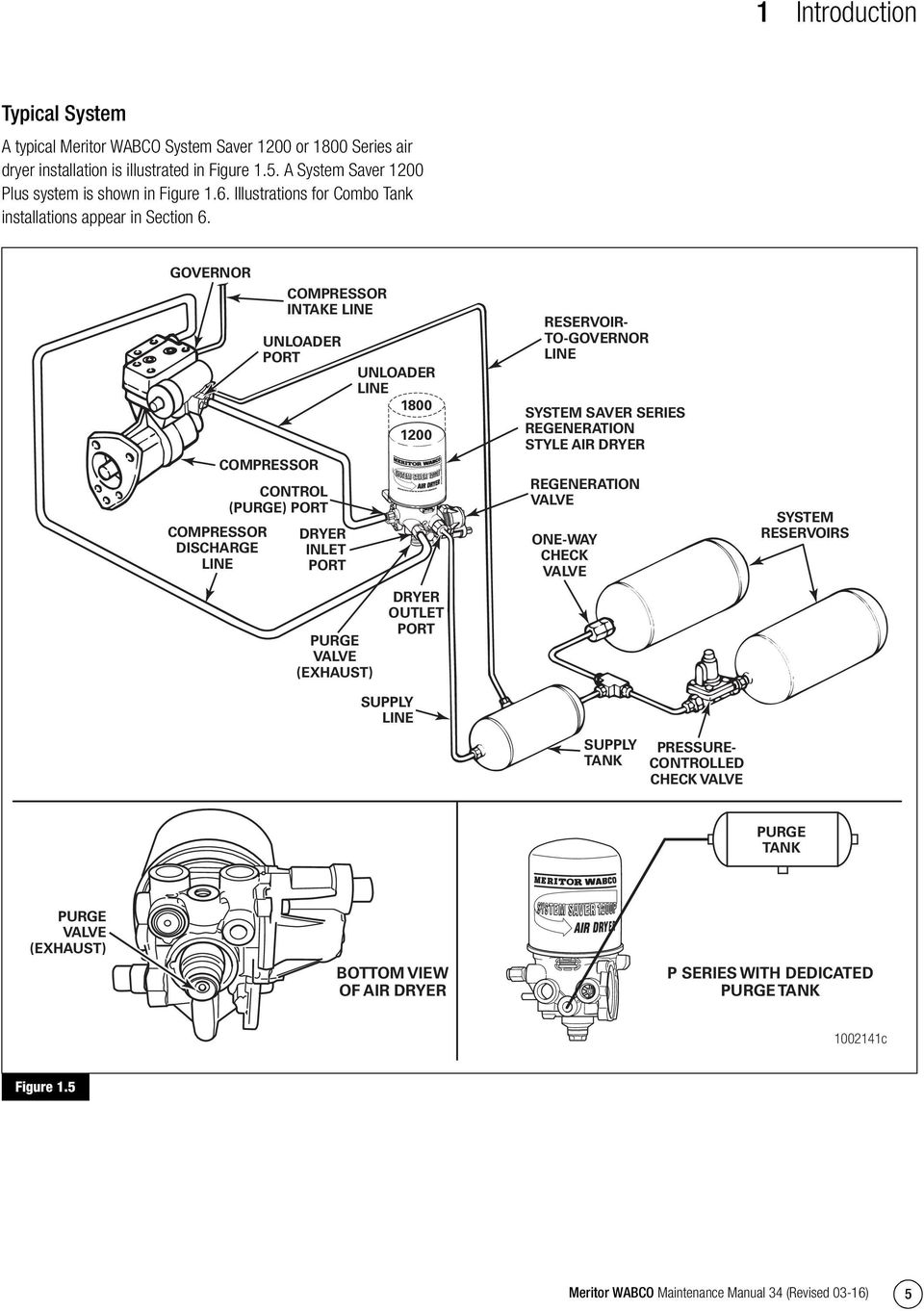

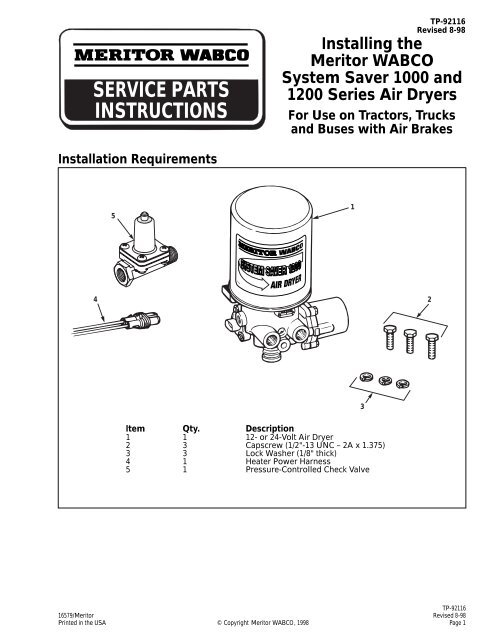

TP-92116, Installing the Meritor WABCO System Saver Series Air Dryer, provides complete installation instructions. System Saver 1200E: Tubing and banjo fitting at front of dryer PB-8857AS contains a complete listing of air dryer replacement System Saver 1200P/1800P: Uses dedicated purge tank. Port 22 parts.

Meritor WABCO System Saver Single Cartridge Air Dryer Publications MM34 Maintenance Manual PB-96134 Parts Book TP-9672 Air Dryer Application Guidelines TP-9772 26” x 40” Troubleshooting Guide Wall Chart TP-97101 Troubleshooting Guide (laminated card) T-97105V Troubleshooting and Repair Video

Air dryer rebuilds can be stretched to every 36 months when the AD-9 is installed on a typical over-the-road truck or tractor. Easy To Service Desiccant cartridge replacement is the only reason to ever completely disassemble the Bendix AD-9 air dryer.

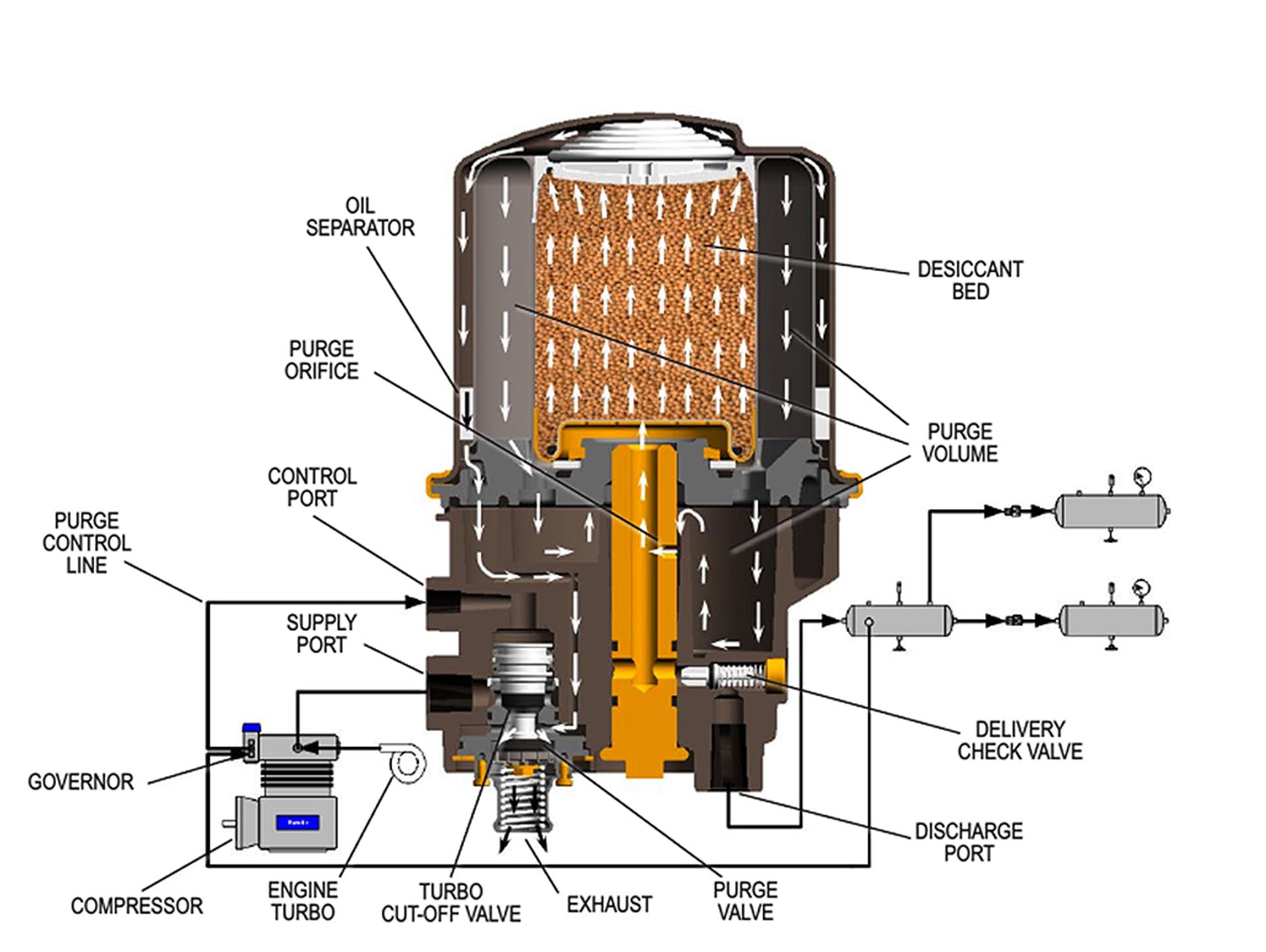

Within the air dryer system, there are three key components to monitor: the air dryer cartridge, the purge valve, and the delivery check valve. 85, Save 37% NEW ITEM. AIR COMPRESSOR The air compressor is the source of energy for the air brake system. Peterbilt A/C Air Compressor 5256 York Style Kenworth Air Compressor. 99 shipping + AU .

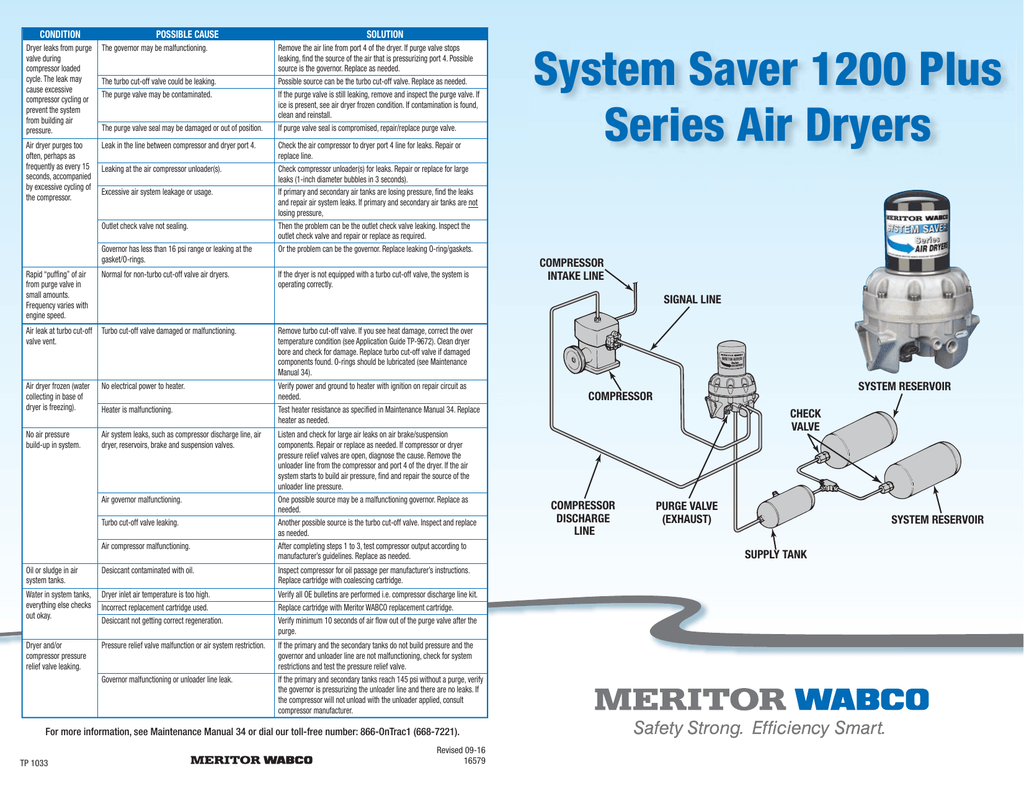

the compressor remains cut out: The air dryer is a non-turbo cut-off valve or DLU air dryer. The dryer can be used with PACCAR twin-cylinder compressors. If, after 30 seconds while the compressor is still in cut-out mode, and the air stops fl owing out the bottom of the dryer: The air dryer is most likely a turbo cut-off valve dryer. The air dryer

System Saver - Air Dryer 1200 plus - WABCO Catalog. Trailer. Air Storage. a1i3X000005gIZY. Drain valve. Air Brake Systems. Anti-Lock Braking System (ABS) ABS Electronic Control Unit (ECU) ABS Cables.

Air dryer, service brake : Column, steering : Hook pintle : Outrigger extension cylinder : Swing solenoid : Air line shuttle valve : Control - fly telescope : Hydraulic air actuator : Outrigger floats : Swing warning : Air lines and fittings : Control - lift : Hydraulic manifold : Outrigger floats : Telescope cylinder holding valve : Air ...

At the vent of the air dryer, the regenerating air must flow out for approx. 10 seconds. Schematic for Testing and. Installation. Schematic 1: Schematic 2. Manual 35, Meritor WABCO System Saver TWIN Air Dryer. To obtain .. Check the entire air system for leaks, and repair as necessary.

Washer/Dryer. Some links on this page are to other sites. Some are manufacturer's sites and some are other independent sites like this one. When possible, credit is given to the source of the information. If you have found a good source of information, please let me know. Air Brake System & other Compressed Air Devices. Air Dryer By-pass Appliances

publication, or for more information about the Meritor WABCO product line, please contact the OnTrac Customer Service Center at 866-OnTrac1 (668-7221) or visit our website, meritorwabco.com. Introduction If the air dryer were to malfunction in a way that the air compressor cannot build up pressure within the system and the air dryer cannot

System Saver Series Single Cartridge Air Dryers TP-92116, Installing the WABCO System Saver Series Air Dryer, provides complete installation instructions. PB-8857AS contains a complete listing of air dryer replacement parts. TP-97101 is a troubleshooting guide. There is also a poster-sized troubleshooting guide, TP-9772, available.

Nov 04, 2017 · Freightliner m2 bulkhead module diagram. For both vertical and horizontal position, connect airlines from the air spring to the air spring(s) port(s) as shown in Figure 3. Air Fitting 8. Tractor trailer air brake system diagram air brake 2018 freightliner cascadia with 156 inch ari legacy ii rbsd sleeper. eCascadia eM2.

If the dryer is not equipped with a turbo cut-off valve, the system is operating correctly. Normal for non-turbo cut-off valve air dryers. Air leak at turbo cut-off valve vent. Remove turbo cut-off valve. If you see heat damage, correct the over temperature condition (see Application Guide TP-9672). Clean dryer bore and check for damage.

0 Response to "37 wabco air dryer diagram"

Post a Comment